Case study

TRAC Intermodal Fleet Modernization Meets Chassis Supply Challenges

About the Case Study

“TRAC’s Refurbished Blue Edge Chassis allow motor carriers to obtain equipment to cover our needs with all the peaks and valleys that we are faced with in the short and long term on handling our imports…Flexibility is most important to us and this program is beneficial to us financially for both door and merchant haulage.”

Steve Schulein

VP, Drayage and Industry Relations, NRT

Record import volumes in recent years have sparked strong usage of marine chassis. This demand has put pressure on available units and constrained supply. Stockpiled inventory idled thousands of chassis with containers at marine terminals, railyards and other locations around the country. This sparked prolonged dwell times, some 2-3 times longer than normal.

Retaliatory duties on chassis manufactured in China and a limited response by domestic and off-shore manufacturers compounded the supply problem. TRAC President and CEO Dan Walsh admitted last summer that “chassis supplies materially lag customer demand.”

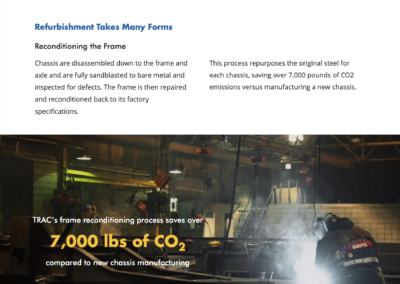

In response, TRAC Intermodal chose innovation to expand its marine chassis pool. This path involved a massive investment by the company in fleet modernization, more than $1 billion since 2015, to purchase new equipment and optimize its existing fleet assets. TRAC’s case study describes its ambitious effort to repurpose existing equipment through a comprehensive refurbishment process to boost chassis availability when customers needed it most.

“The new refurbished TRAC Blue Edge Chassis program has been very beneficial to our operation with consistent reliable equipment which keeps our drivers moving without costly repairs and lost time . I would recommend this type of chassis moving forward to other companies looking to get a reliable piece of equipment at a reasonable cost great ROI for your company.”

James O’Neill

EVP Transportation and Support Services, O’Neill Logistics